Aluminum Foundry and Wisconsin Aluminum Foundry: building a strong future

Wiki Article

The Numerous Usages of Aluminum Castings: A Comprehensive Guide for Industry Professionals

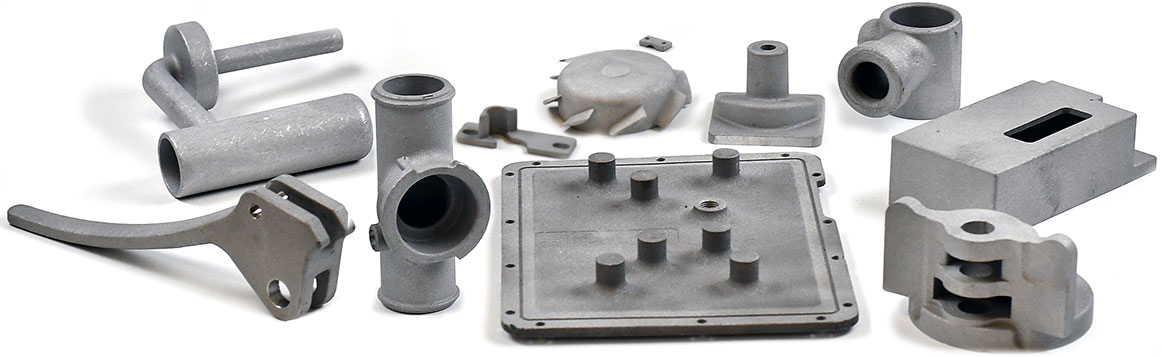

Aluminum spreadings play an essential function throughout various markets, many thanks to their one-of-a-kind properties. These resilient and lightweight elements are crucial in automobile and aerospace applications. Understanding their benefits and the production processes entailed can significantly affect performance and performance. As technology advancements, new developments remain to emerge. Sector professionals should think about these elements to make educated choices. The effects of these advancements deserve exploring better.Advantages of Aluminum Castings in Different Industries

Aluminum castings supply many advantages throughout numerous sectors, making them a preferred choice for numerous applications. One of the primary benefits is their light-weight nature, which adds to general energy performance in transportation and equipment. This minimized weight additionally enhances convenience of handling and setup, bring about reduced labor costs.Aluminum castings display superb rust resistance, extending the lifespan of elements in severe settings. Their electric and thermal conductivity enables effective heat dissipation and reliable electric applications.

Furthermore, aluminum can be easily alloyed and manipulated, making it possible for the creation of complex forms and designs that meet details engineering needs. This convenience sustains technology in sectors such as auto, aerospace, and durable goods.

The recyclability of light weight aluminum aligns with sustainable practices, making it an ecologically pleasant option for modern-day production. In general, the benefits of aluminum spreadings position them as essential products in numerous fields.

Key Production Processes for Light Weight Aluminum Castings

A selection of manufacturing procedures are made use of to create aluminum castings, each tailored to fulfill specific application needs and production quantities. Among the most usual methods are sand spreading, die casting, and investment casting.

Investment spreading, also referred to as lost-wax casting, offers exceptional surface area coatings and elaborate details, commonly used for smaller, precision parts. Additionally, gravity casting makes use of the force of gravity to fill molds, ideal for bigger castings where precision is much less important. Each procedure has its advantages, accommodating varied commercial demands while maximizing performance and quality in aluminum casting production.

Applications of Aluminum Castings in Automotive and Aerospace

In numerous applications within the aerospace and automobile sectors, aluminum spreadings play a crucial duty due to their light-weight buildings and outstanding strength-to-weight proportion. In the automotive market, components such as engine blocks, transmission situations, and wheel rims are often created using aluminum castings. These components gain from minimized weight, leading to boosted gas effectiveness and boosted efficiency.In aerospace, aluminum castings are crucial for structural parts, including aircraft structures, touchdown equipment, and engine housings. The material's resistance to deterioration and ability to hold up against heats make it suitable for these requiring applications. Additionally, aluminum castings assist in complex geometries, making it possible for the design of complex parts that add to general pop over to this site airplane efficiency.

Developments and Developments in Light Weight Aluminum Spreading Technology

As industries remain to develop, developments in aluminum casting modern technology are driving substantial renovations in performance and performance. Advanced techniques such as 3D printing and casting simulation software have transformed standard methods, allowing for much more specific designs and lowered waste. These innovations allow manufacturers to produce complex geometries that were formerly unattainable, enhancing the flexibility of aluminum spreadings.In addition, the growth of brand-new alloy structures and treatment techniques has actually improved mechanical properties, making spreadings lighter yet stronger. Automated processes are additionally being integrated, decreasing human mistake and boosting manufacturing rate.

Finest Practices for Making Use Of and selecting Aluminum Castings

When selecting and utilizing aluminum castings, careful factor to consider of certain criteria can substantially these details influence the final item's performance and durability. Market experts must evaluate the particular application needs, including load-bearing capacities, corrosion resistance, and thermal conductivity. Picking the ideal alloy is important, as various alloys offer differing qualities and toughness.Additionally, understanding the spreading process-- whether sand casting, die casting, or financial investment spreading-- will affect the last product's high quality and cost-effectiveness. Quality guarantee steps, such as non-destructive screening and dimensional evaluations, are crucial to ensure that the castings satisfy sector criteria.

Correct handling and storage space of light weight aluminum castings can protect against damages, guaranteeing peak performance. Lastly, working together with trustworthy vendors that prioritize high quality control can boost the integrity of the finished parts. By sticking to these best techniques, sector specialists can make best use of the advantages of light weight aluminum castings in their applications.

Regularly Asked Questions

What Are the Environmental Impacts of Aluminum Spreading Production?

Light weight aluminum spreading manufacturing can bring about substantial environmental impacts, including greenhouse gas emissions, energy usage, and resource depletion. Additionally, incorrect waste management may cause soil and water contamination, impacting neighborhood ecosystems and neighborhoods.Exactly How Do Aluminum Castings Compare to Various Other Metal Spreadings?

Light weight aluminum castings are lighter and corrosion-resistant compared to various other metal spreadings like iron or steel. They supply remarkable thermal and electric conductivity, making them suitable for applications get more where weight and toughness are important aspects.What Is the Cost Difference In Between Aluminum and Various Other Materials?

The cost of aluminum castings usually varies from moderate to high, often a lot more cost effective than stainless-steel however costlier than some plastic options. Aluminum Castings. Variables such as production material, quantity, and intricacy requirements significantly influence total pricesCan Light Weight Aluminum Castings Be Reused?

Light weight aluminum castings can indeed be reused. This process considerably decreases energy usage and ecological effect contrasted to producing brand-new aluminum, making reusing an important method in promoting sustainability and resource preservation within various sectors.

What Precaution Should Be Taken Throughout Aluminum Spreading Processes?

During light weight aluminum casting procedures, important safety and security actions consist of using safety gear, guaranteeing appropriate ventilation, utilizing heat-resistant tools, maintaining equipment, and following safety protocols to stop exposure to hazardous materials and reduce the threat of crashes. (Metal Castings)Sand spreading includes creating a mold and mildew from sand, allowing for big castings and complicated forms. Investment spreading, additionally recognized as lost-wax spreading, offers remarkable surface finishes and detailed details, commonly used for smaller sized, accuracy parts. In addition, gravity casting makes use of the pressure of gravity to fill mold and mildews, suitable for bigger spreadings where precision is much less vital. Additionally, comprehending the spreading process-- whether sand spreading, die spreading, or financial investment spreading-- will certainly affect the final item's high quality and cost-effectiveness. Aluminum castings are lighter and corrosion-resistant contrasted to various other steel spreadings like iron or steel.

Report this wiki page